Context:

In a significant recommendation, a committee led by Principal Scientific Advisor (PSA) Ajay Sood has advised the Indian government to roll back its 2015 policy mandating Flue Gas Desulphurisation (FGD) units in all coal-fired thermal power plants (TPPs). This has reignited the debate on balancing energy needs, costs, and public health

About Flue Gas Desulphurisation (FGD):

Flue Gas Desulphurisation (FGD) units are designed to remove sulphur dioxide (SO₂) emissions from the exhaust of thermal power plants. SO₂ is released when coal is burned and contributes significantly to air pollution and climate change. It also leads to the formation of PM2.5, a dangerous form of particulate matter linked to respiratory and cardiovascular diseases.

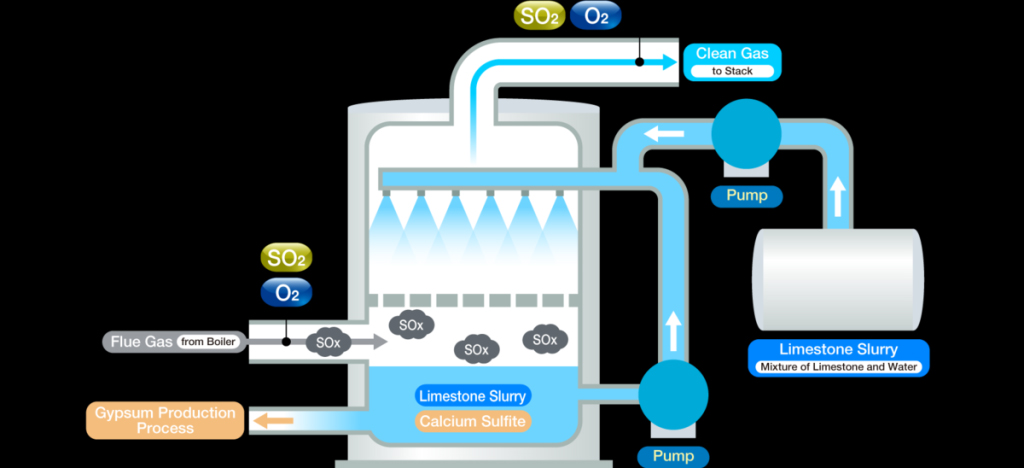

FGDs work by treating the flue gas with a basic compound to neutralise the acidic SO₂. The three main FGD technologies in use are:

- Dry Sorbent Injection: Uses powdered limestone or other sorbents that react with SO₂, removed through filters.

- Wet Limestone Treatment: Uses limestone slurry to convert SO₂ into gypsum, an industrial byproduct. This is the most efficient and widely used method.

- Seawater-Based FGDs: Adopted in coastal areas, where seawater absorbs SO₂ and is then treated before discharge.

Concerns regarding SO₂ emissions:

Sulphur dioxide contributes to both climate warming and public health problems. It forms secondary particulates that significantly increase PM2.5 levels in the air. Research has shown that 15% of India’s PM2.5 pollution is linked to coal-fired power plants, with 80% of that due to SO₂ emissions. These emissions are harder to regulate but have far-reaching impacts on human health and air quality.

The 2015 FGD mandate:

In 2015, the Ministry of Environment, Forest and Climate Change required all 537 coal-fired TPPs to install FGDs by 2018. However, the implementation has been extremely slow:

- As of April 2025, only 39 plants have installed FGDs.

- Deadlines have been extended to 2027, 2028, and 2029, depending on plant category.

- In December 2024, the government further extended deadlines without explanation.

- A government-commissioned study in 2025 recommended repealing the FGD mandate altogether.

Concerns against FGD installation:

FGD units are expensive, with the Central Electricity Authority estimating a cost of ₹1.2 crore per megawatt (MW).

India’s coal-based capacity stood at 2,19,338 MW in April 2025, almost half of the total electricity generation capacity. Installing FGDs across this capacity would cost over ₹2.6 lakh crore.

Officials argue that with 97,000 MW of new coal-based power expected, FGD compliance would add ₹97,000 crore to infrastructure costs and could raise consumer tariffs. This economic argument is driving calls to ease or withdraw the mandate.

However, researchers counter this by noting:

· FGDs would raise tariffs by only ₹0.72 per kWh — mostly due to fixed costs.

· Variable costs remain under ₹0.10 per kWh, making the impact manageable.

· Cleaner air reduces healthcare costs, improves productivity, and prevents premature deaths — creating long-term economic savings.

Conclusion:

There is no viable alternative to FGDs for removing SO₂ emissions. Coal washing does not remove sulphur embedded in the coal’s structure. With coal consumption expected to increase, especially among older, inefficient, state-run plants, skipping FGD compliance could severely degrade air quality.

Abandoning the FGD mandate would also weaken the National Clean Air Programme (NCAP), which has seen over ₹6,000 crore in investments. It risks reversing gains made in air quality management and environmental protection.