Context:

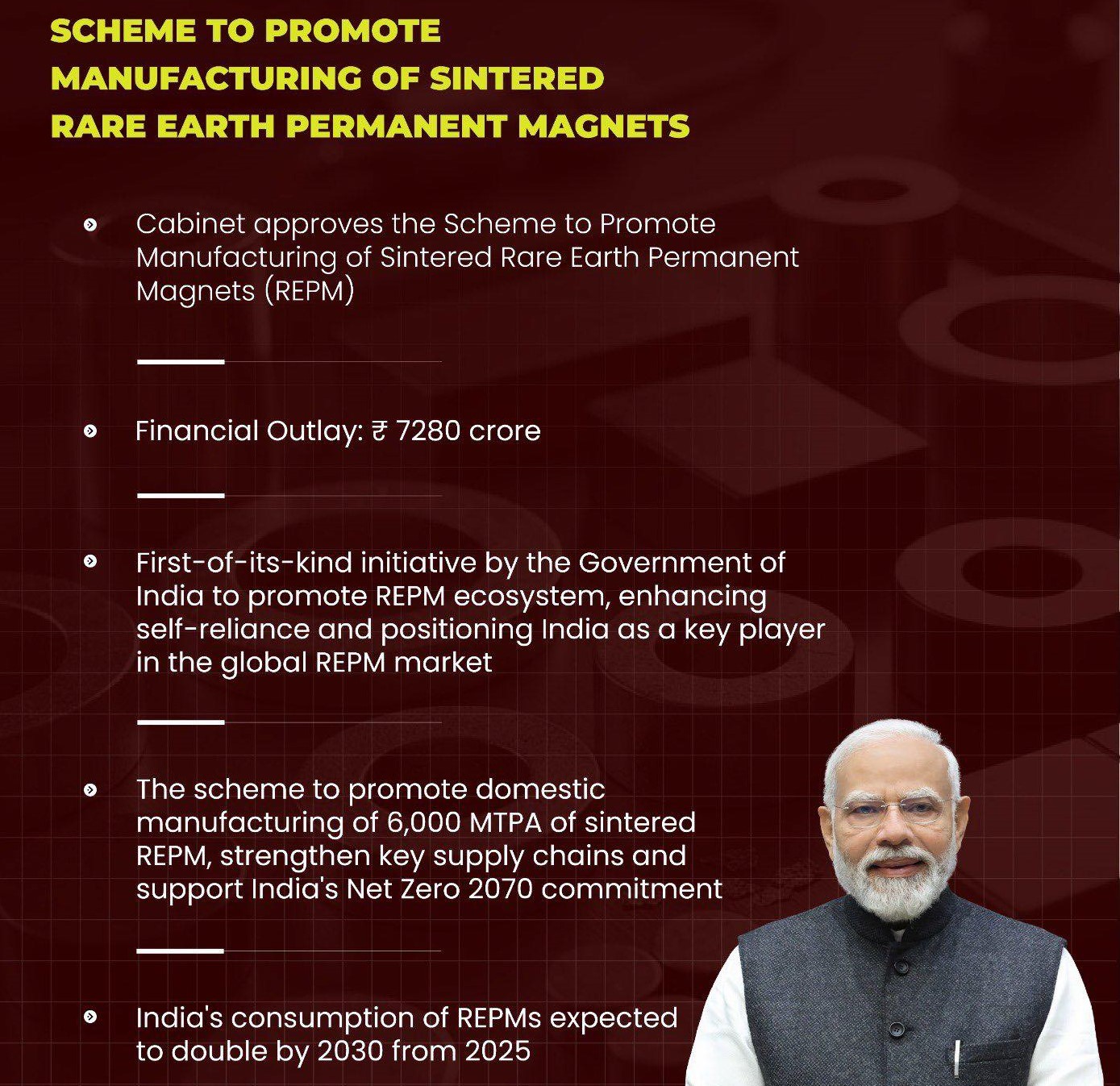

On 26 November 2025, the Union Cabinet of India approved ‘Scheme to Promote Manufacturing of Sintered Rare Earth Permanent Magnets (REPM)’ to promote domestic manufacturing of sintered Rare Earth Permanent Magnets (REPM). The initiative marks India’s first comprehensive drive to build an end‑to‑end magnet production ecosystem.

Why the Policy Matters:

-

- REPMs — powerful magnets made from rare‑earth elements — are critical components in high‑growth, high‑technology sectors: electric vehicles (EVs), renewable energy (wind turbines), defence, aerospace, electronics, medical equipment, and more.

- Until now, India has depended on imports to meet its REPM demand. This reliance poses a strategic vulnerability, especially in the wake of recent global supply disruptions and export restrictions imposed by leading suppliers - particularly in China, which dominates REPM refining and processing worldwide.

- With demand for REPMs expected to double by 2030, the new scheme seeks to ensure supply‑chain security, reduce import dependence, and support India’s growing ambitions in clean energy, advanced manufacturing, and defence.

- REPMs — powerful magnets made from rare‑earth elements — are critical components in high‑growth, high‑technology sectors: electric vehicles (EVs), renewable energy (wind turbines), defence, aerospace, electronics, medical equipment, and more.

Key Features of the scheme:

The scheme aims to build a domestic manufacturing capacity of 6,000 Metric Tonnes Per Annum (MTPA) of REPM.

Financial support is divided into:

-

- Sales‑linked incentives worth ₹6,450 crore over five years, to incentivize production and sales of REPMs.

- Capital subsidy of ₹750 crore to support the establishment of manufacturing facilities.

- Sales‑linked incentives worth ₹6,450 crore over five years, to incentivize production and sales of REPMs.

The overall scheme spans seven years, including a two-year gestation period for plant set-up and five years for incentive eligibility.

The manufacturing facilities supported under this scheme will cover the full value‑chain: from converting rare-earth oxides to metals, metals to alloys, and finally producing finished permanent magnets.

Anticipated Impacts:

-

- Supply‑chain security and self‑reliance: With domestic REPM production, India can insulate critical industries (EVs, defence, aerospace, renewables) from global supply shocks and geo‑political risks associated with import dependence.

- Boost to high‑technology manufacturing: Establishing REPM plants will catalyse growth in ancillary sectors — mining, alloy processing, advanced materials — and support India's broader push for advanced manufacturing and clean-tech adoption.

- Employment and investment: Implementation of the scheme can generate jobs in manufacturing, supply‑chain logistics, and downstream industries, while attracting investments in high‑tech fabrication.

- Support for energy transition and Net‑Zero commitment: As India accelerates deployment of green technologies (EVs, renewable energy), domestic REPM supply will be critical. This aligns with national targets such as achieving Net‑Zero emissions by 2070.

- Supply‑chain security and self‑reliance: With domestic REPM production, India can insulate critical industries (EVs, defence, aerospace, renewables) from global supply shocks and geo‑political risks associated with import dependence.

Conclusion:

The ₹7,280‑crore REPM scheme marks India’s shift from importer to global manufacturer of rare‑earth magnets, enhancing strategic autonomy, supply‑chain security, and growth in EVs, clean energy, defence, and high‑tech sectors. By combining incentives, competitive bidding, and a full value‑chain ecosystem, it could become a cornerstone of “Make in India” and “Atmanirbhar Bharat,” driving a sustainable, high‑growth, technologically advanced economy by 2047.