Context:

Indian researchers have developed a cost-effective, metal-free catalyst capable of efficiently producing hydrogen fuel by harnessing mechanical energy. This innovation represents a significant advancement in green hydrogen technology, offering a promising alternative to fossil fuels and contributing to global efforts toward sustainable energy solutions.

Research Overview:

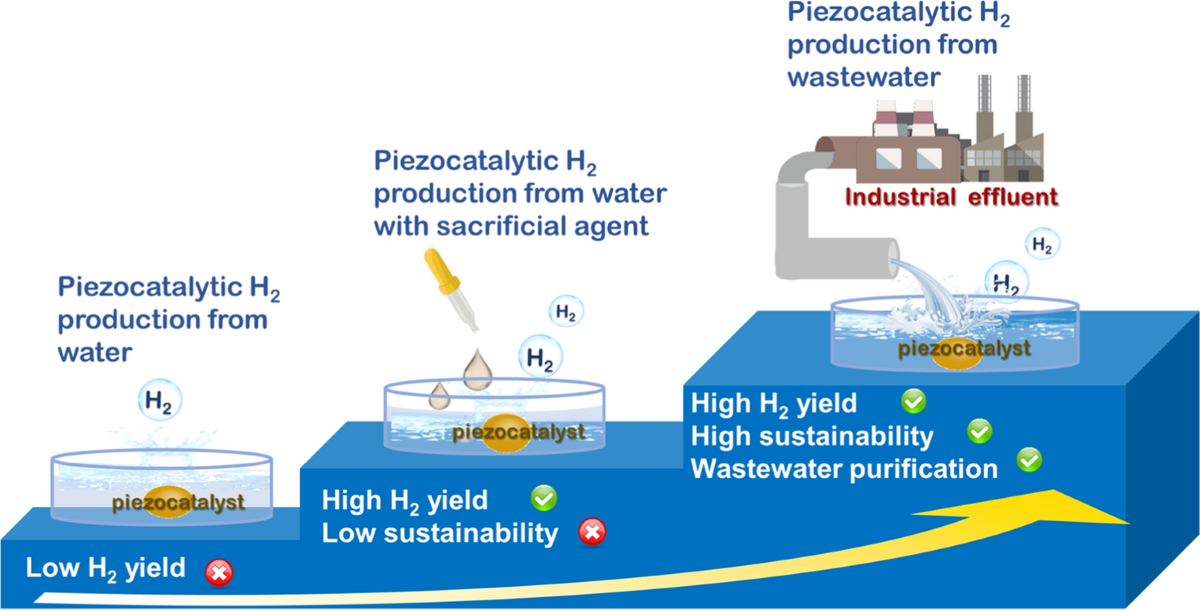

- This research introduces a donor-acceptor based covalent organic framework (COF) that functions as an efficient piezocatalyst for water splitting, a process that separates hydrogen from water molecules. Unlike conventional catalysts that rely on metal-based ferroelectric materials, the new COF system is entirely organic and metal-free.

- The COF is composed of tris(4-aminophenyl)amine (TAPA) as the donor molecule and pyromellitic dianhydride (PDA) as the acceptor. These materials form imide linkages, which give rise to ferrielectric (FiE) ordering, a structural feature that enhances the catalyst’s efficiency in water splitting.

Key Features of the COF System

- The novel COF system stands out due to its sponge-like porous architecture, which facilitates water diffusion and charge carrier access. The FiE ordering within the framework generates local electric fields at the pore surfaces, enabling high-density charge accumulation. This contributes to the high yield of hydrogen fuel during the water-splitting reaction.

- Additionally, the COF operates based on a piezocatalytic mechanism. The COF's electronic structure, characterized by coupled energy bands and dipolar ordering, creates lattice instability. This instability allows for dynamic interaction with mechanical stimuli such as pressure or vibrations. When subjected to mechanical force, the material generates electron-hole pairs, catalyzing the water-splitting reaction with exceptional efficiency.

Implications for Hydrogen Production:

· Metal Elimination: Unlike conventional methods that depend on expensive and harmful metals, this COF system eliminates the need for metals, reducing costs and environmental impact.

· Sustainability and Cost-efficiency: By utilizing organic, abundant materials, this approach provides a more cost-effective and sustainable solution to hydrogen production.

· Utilizing Ambient Mechanical Energy: The COF system harnesses ambient mechanical energy, such as vibrations or pressure, for clean energy generation, offering a more efficient method compared to traditional energy inputs.

· Alignment with India's Green Hydrogen Mission: This breakthrough supports India’s National Green Hydrogen Mission, advancing large-scale green hydrogen production and reinforcing India's position as a global leader in hydrogen energy.

· Global Impact on Renewable Energy: The metal-free piezocatalyst contributes to the transition to clean, renewable energy, reducing reliance on fossil fuels and supporting global sustainability efforts.

Conclusion:

The development of a metal-free piezocatalyst for hydrogen production represents a groundbreaking achievement in green hydrogen technology. By eliminating the need for metals and utilizing ambient mechanical energy, this COF system provides a scalable, sustainable, and efficient approach to hydrogen production. This innovation holds the potential to significantly contribute to global efforts in renewable energy, driving progress in the hydrogen economy.