Brain-booster

/

06 Sep 2022

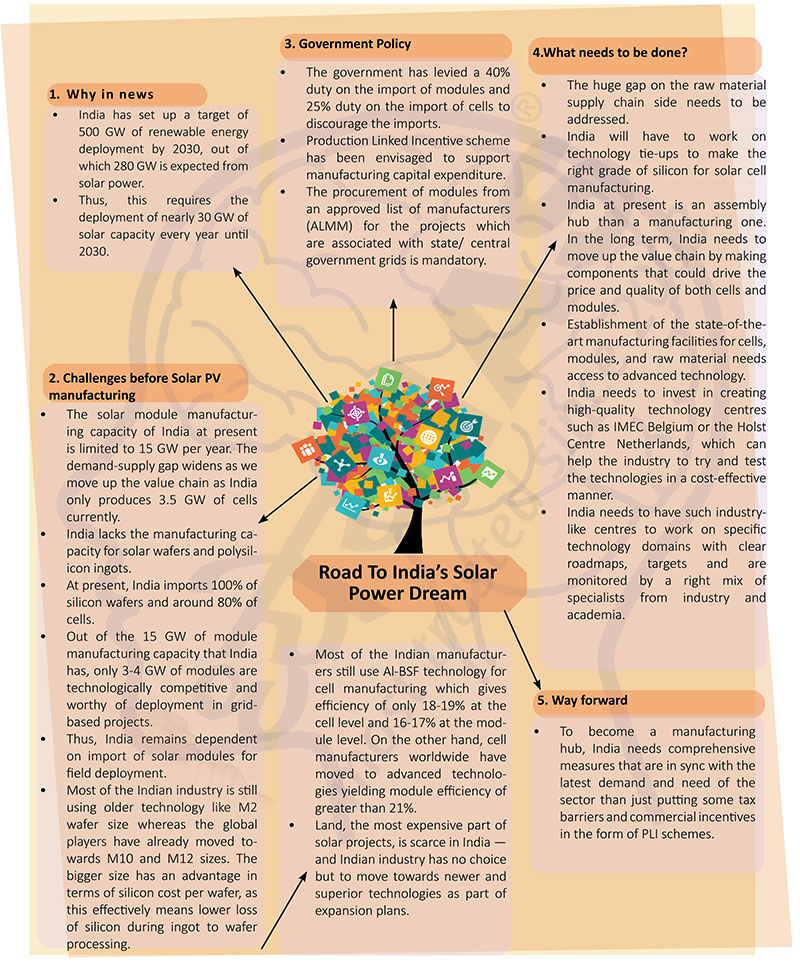

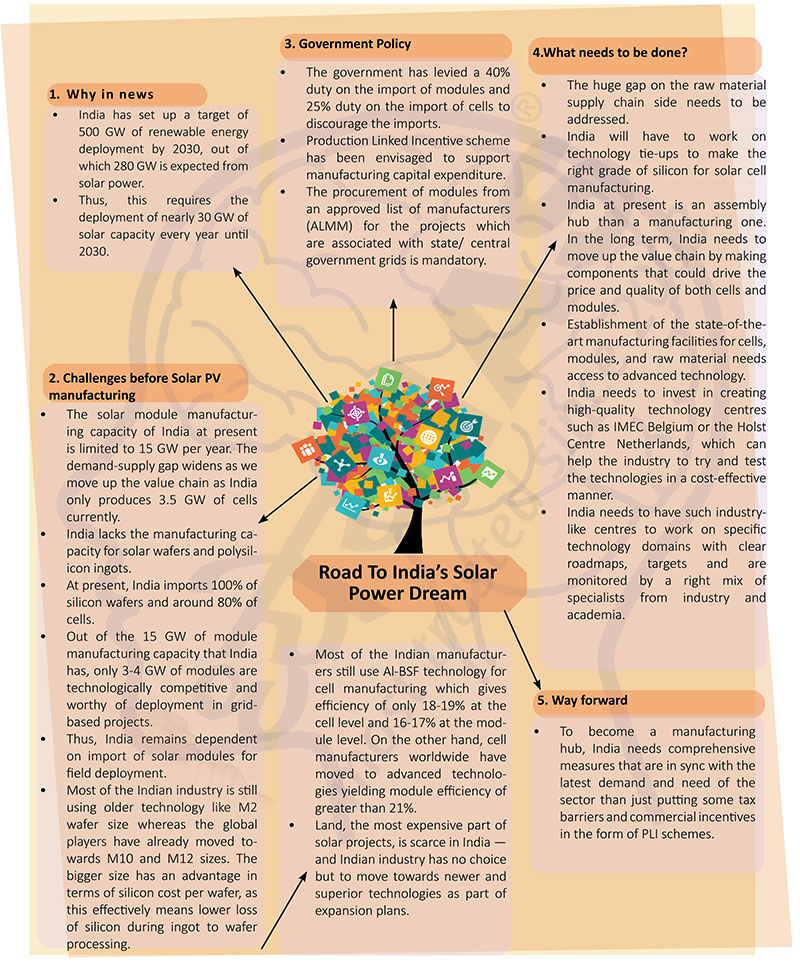

Brain Booster for UPSC & State PCS Examination (Topic: Road to India’s Solar Power Dream)

Why in news?

- India has set up a target of 500 GW of renewable energy deployment by

2030, out of which 280 GW is expected from solar power.

- Thus, this requires the deployment of nearly 30 GW of solar capacity

every year until 2030.

Challenges before Solar PV manufacturing

- The solar module manufacturing capacity of India at present is limited

to 15 GW per year. The demand-supply gap widens as we move up the value

chain as India only produces 3.5 GW of cells currently.

- India lacks the manufacturing capacity for solar wafers and polysilicon

ingots.

- At present, India imports 100% of silicon wafers and around 80% of

cells.

- Out of the 15 GW of module manufacturing capacity that India has, only

3-4 GW of modules are technologically competitive and worthy of deployment

in gridbased projects.

- Thus, India remains dependent on import of solar modules for field

deployment.

- Most of the Indian industry is still using older technology like M2

wafer size whereas the global players have already moved towards M10 and M12

sizes. The bigger size has an advantage in terms of silicon cost per wafer,

as this effectively means lower loss of silicon during ingot to wafer

processing.

- Most of the Indian manufacturers still use Al-BSF technology for cell

manufacturing which gives efficiency of only 18-19% at the cell level and

16-17% at the module level. On the other hand, cell manufacturers worldwide

have moved to advanced technologies yielding module efficiency of greater

than 21%.

- Land, the most expensive part of solar projects, is scarce in India —

and Indian industry has no choice but to move towards newer and superior

technologies as part of expansion plans.

Government Policy

- The government has levied a 40% duty on the import of modules and 25%

duty on the import of cells to discourage the imports.

- Production Linked Incentive scheme has been envisaged to support

manufacturing capital expenditure.

- The procurement of modules from an approved list of manufacturers (ALMM)

for the projects which are associated with state/ central government grids

is mandatory.

What needs to be done?

- The huge gap on the raw material supply chain side needs to be

addressed.

- India will have to work on technology tie-ups to make the right grade of

silicon for solar cell manufacturing.

- India at present is an assembly hub than a manufacturing one. In the

long term, India needs to move up the value chain by making components that

could drive the price and quality of both cells and modules.

- Establishment of the state-of-theart manufacturing facilities for cells,

modules, and raw material needs access to advanced technology.

- India needs to invest in creating high-quality technology centres such

as IMEC Belgium or the Holst Centre Netherlands, which can help the industry

to try and test the technologies in a cost-effective manner.

- India needs to have such industrylike centres to work on specific

technology domains with clear roadmaps, targets and are monitored by a right

mix of specialists from industry and academia.

Way forward

- To become a manufacturing hub, India needs comprehensive measures that

are in sync with the latest demand and need of the sector than just putting

some tax barriers and commercial incentives in the form of PLI schemes.